Retro Fit: A Solution

by EW-Tec

Yesterday’s tech holds

tomorrow’s results.

Rely on what you have.

And on what you could have.

They don’t build them like they used to. This holds especially true for automatic systems, whose metals and materials are still of excellent quality even when their inner workings are outdated. In the interest of sustainability, we have become specialized in retro-fitting: We renew the technology, but retain as many original components as possible. In doing so, we proceed assiduously through the following steps:

01

Taking inventory

02

Identifying the potential for upgrades

03

Developing customized solutions

04

Implementing the upgrade while minimizing potential disruptions to your operations

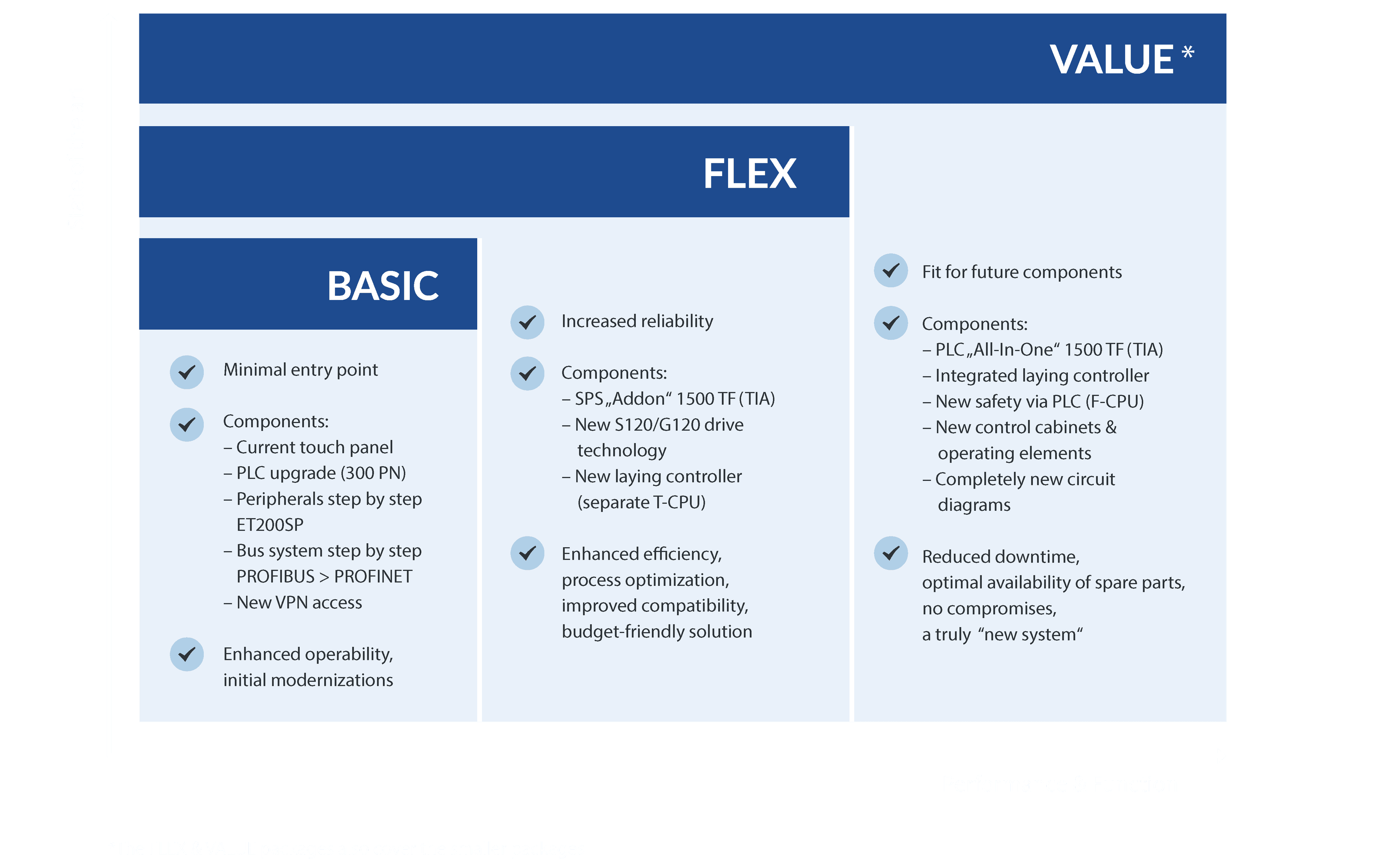

From Basic entry points to a nearly new machine

What we have learned In different retro fit projects we put into packages that makes it easier to find the right solution. The good thing is, you are able to do a step by step update for your machine.

Take a look how I could look like with our longtime partner FUHR rolling mills.

Your production is at risk

The substance of old machinery from past decades is typically still of excellent quality, even though the electrotechnical inner workings are already outdated. The risks associated with outdated control technology are increasing year by year.

In the interest of sustainability, we have specialized in retrofitting. We upgrade the technology whilst retaining as many original components as possible.

The risk of downtime is substantial - many components are no longer available on the market, and employees familiar with the outdated technology are retiring. Another significant factor is the drive systems, which consume excessive amounts of energy. Modernization could yield substantial benefits for you in the future.

Downtime

Downtime Energy consumption

Energy consumption No spare parts

No spare parts Dependency on single employees

Dependency on single employeesThe modular RetroFit concept provides a practical solution to minimize your risks.

A perfect example for the 3 packages is our developed concept with FUHR rolling mills. Thanks to the 3 packages, machines can be upgraded step by step to the state of the art with minimal downtime

This enables you to

- Achieve redundancy of your production

- Boost productivity

- Decrease reliance on individual employees

- Modernize your operations

- Enhance process reliability

- and much more...

Download flyer

Download flyer